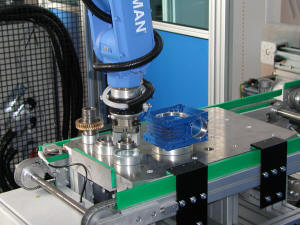

FMS assembly line

The management system with shuttle, warehouse and work stations is the optimal compromise between flexibility, reconfiguration and automation of the assembly phases. Thanks to the control system, based on SQL Server, the operator can store an unlimited number of work cycles, without having to perform complex programming operations; It is sufficient to write some distinct. The collaboration with MotoMan, the largest world manufacturer of industrial robots and Siemens, has allowed optimal integration between line and robotic automation.

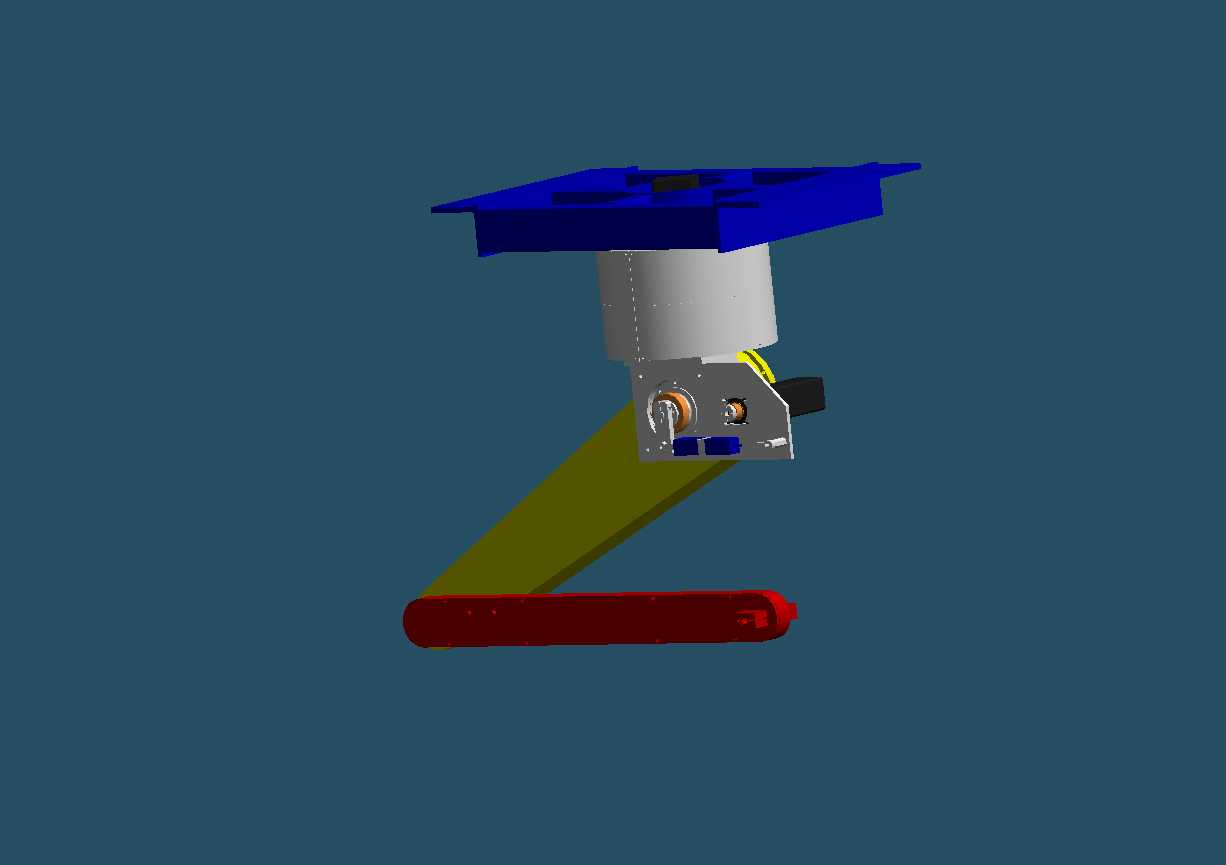

Robots for Stacking

This is a 3-axis system utilized as the vertical axis of a cartesian robot built to pain 3-dimensional objects. The two arms are controlled by a single servo and are linked together in a way that forces the endpoint to travel vertically in a straight line (patented).

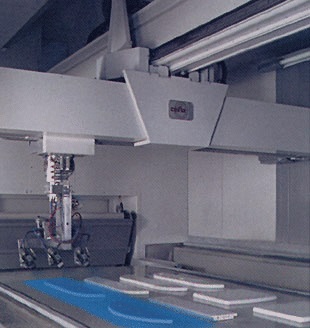

Cartesian Robot

This is a cartesian robot used to paint mobile objects. As technical department manager, I coordinated and supervised this project from the early design stage to final implementation. This machine is currently part of CEFLA SCRL‚_Ts offerings.

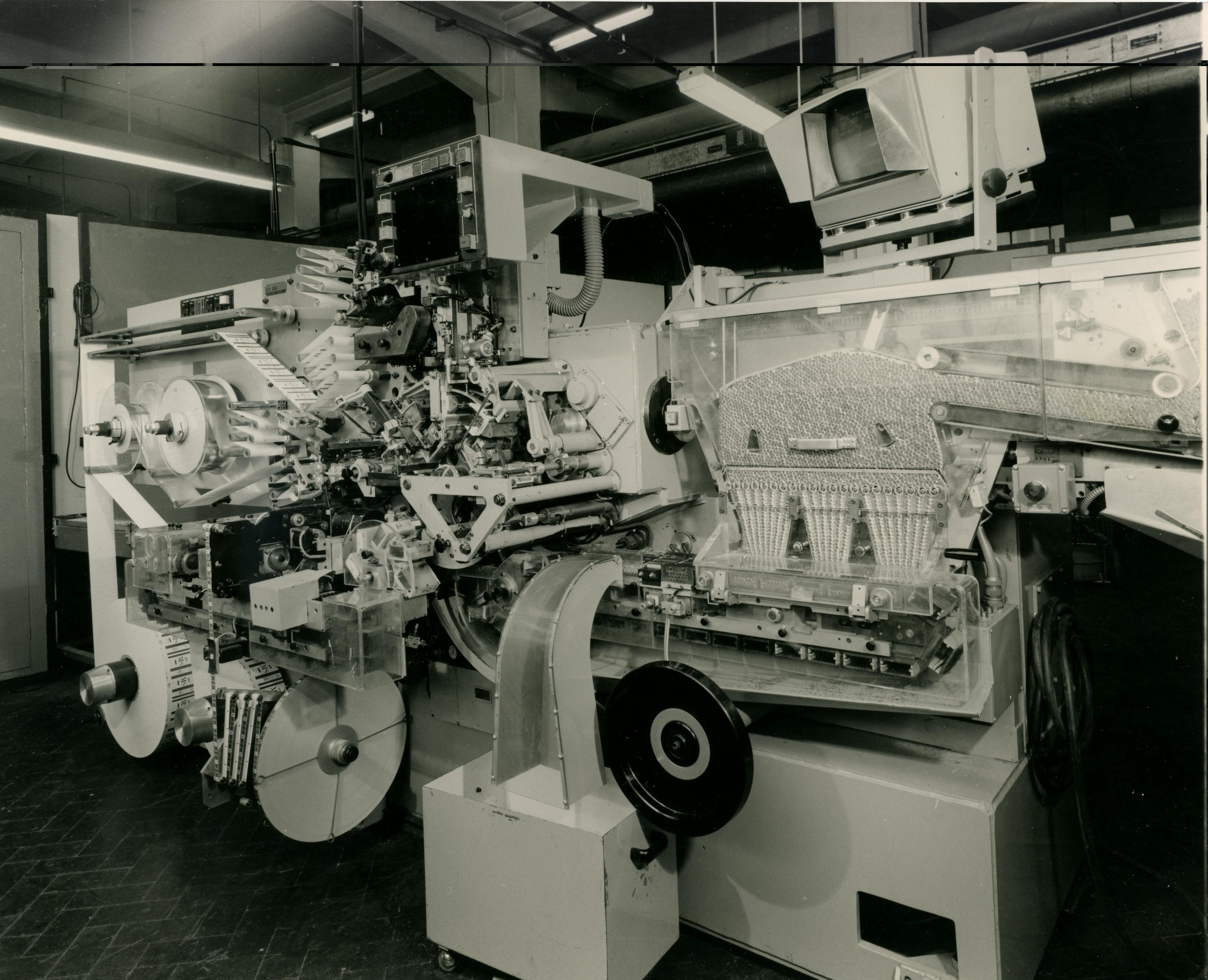

SASIB ALFA packer

Robot for automation of cigarette packing, able to sustain a rate of up to 520 packs per minute.

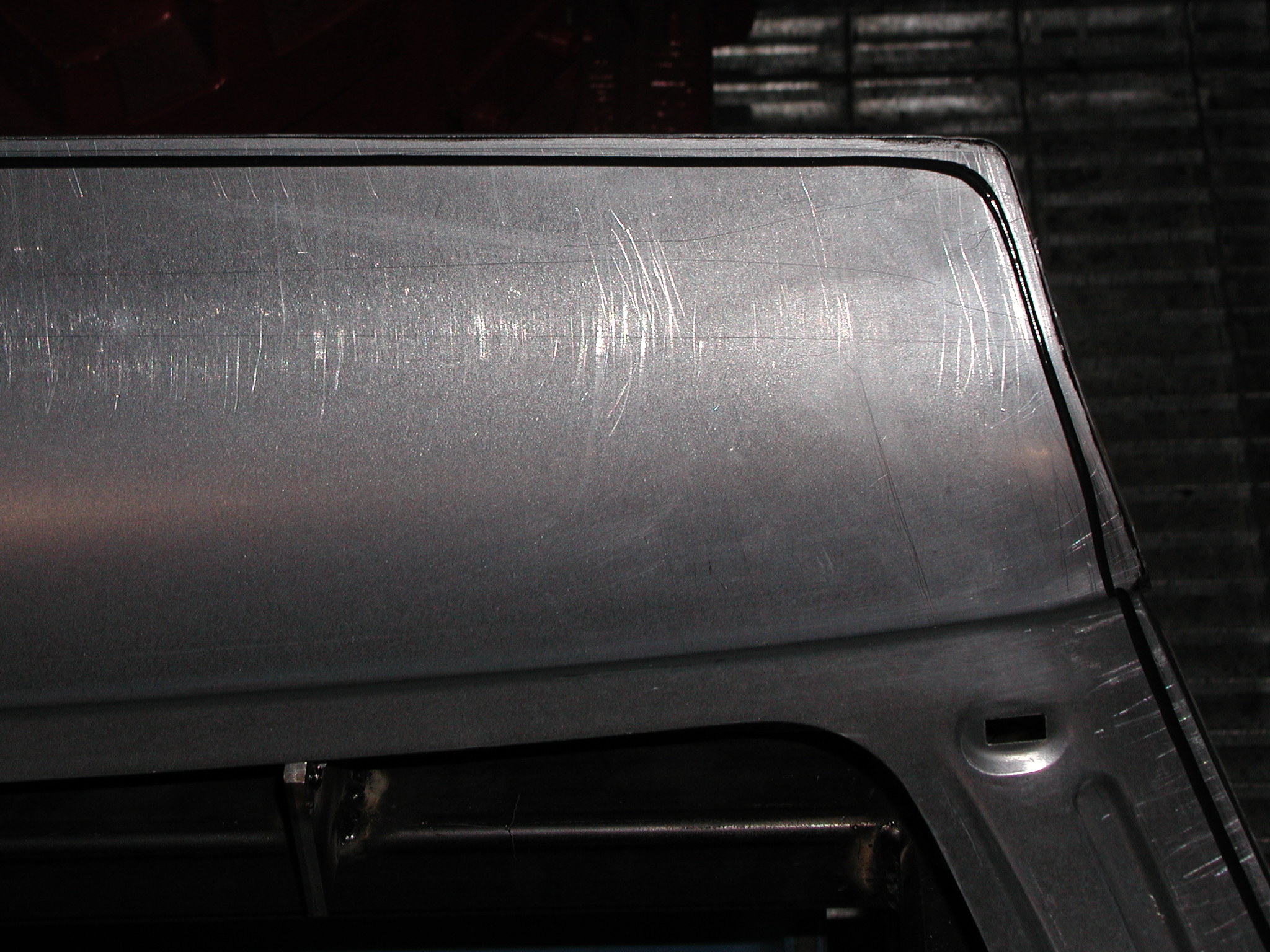

frame sealing

The above-mentioned SWIRL system allows application of sealants at a controllable thickness of 15-30 mm to seal lap weldings.

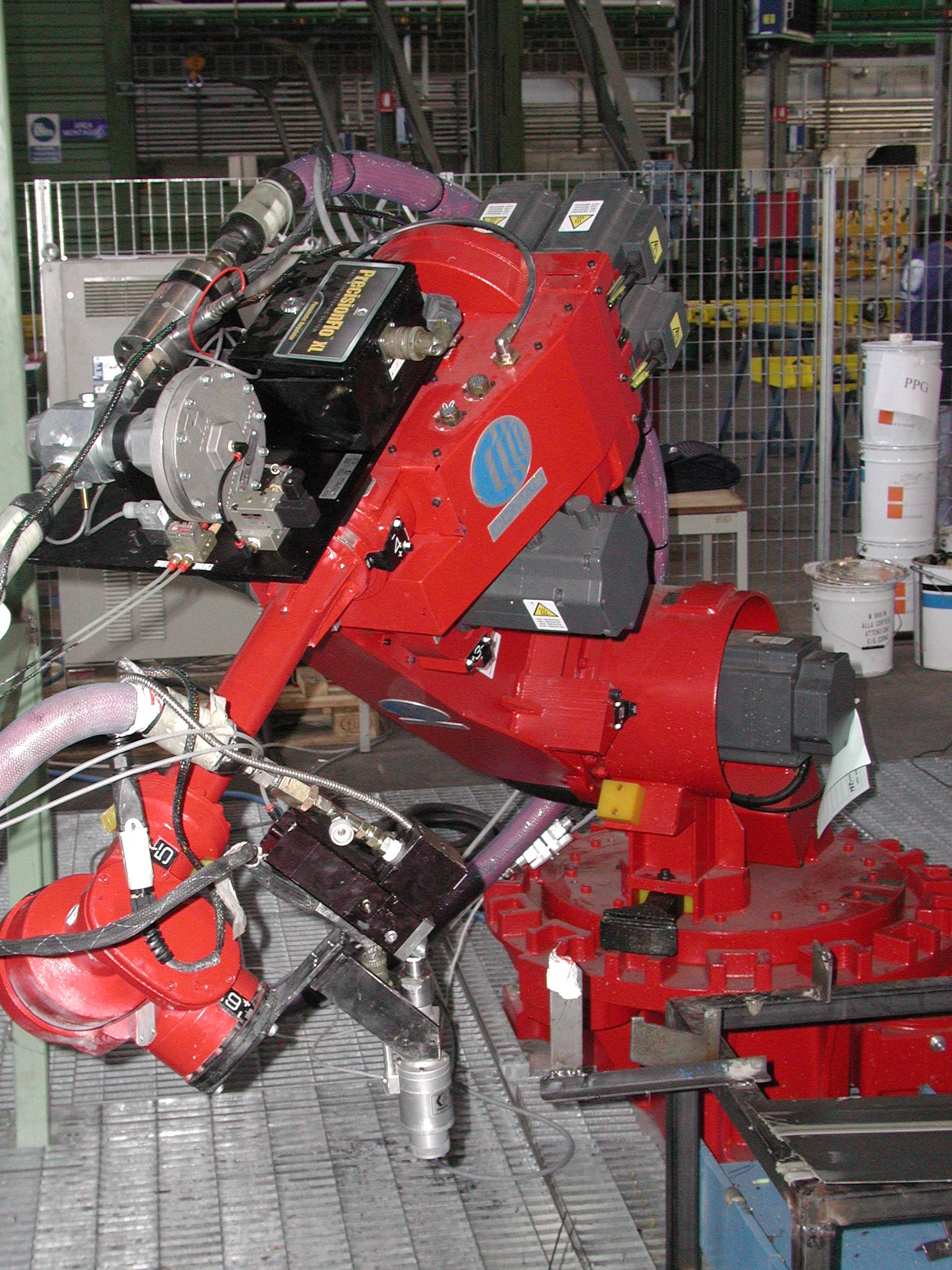

Comau Robot

On behalf of GLFinishing, I coordinated a Comau test facility in Torino Borgaretto, Italy. I was responsible for planning test scenarios with the objective of applying high-viscosity products for automotive clients such as Fiat, Alfa Romeo, Mercedes, Renault. The test system consisted of a Comau robot operating in conjunction with a GRACO-designed delivery system. The delivery system had the following specifications: 5,000 PSI pump 5-zone thermoregulation (1 zone on the pump, 3 zones on the hoses and 1 zone on the nozzle) A PrecisionFlow system for quick retraction of the product, accordingly synced to the velocity of the robot.

Auto Body Hardening

SWIRL also allows application of structural hardening fluids in-lieu of other adhesive sheets.In this situation the application needs to be wider and thicker from 50 to 100 mm.These limits can be exceeded by repeating the application as needed.

Auto Body Hardening

The below picture shows an example of a auto body hardening product on a FIAT vehicle.

Perimetral Gluing

The SWIRL system is also able to apply one-component epoxy adhesives to the perimeter of hoods and door panels.The working speed of the robot is 0.5 meters per second, a door panel or hood can be completely glued in under 11 seconds. Despite the high application velocity, the glue stream is very consistent thanks to the PrecisionFlow which adjusts the nozzle‚_Ts output velocity based on the actual speed of the robot. In order to provide a consistent application quality, the system is able to compensate for the effects generated by variation in glue viscosity.

CMG automation

CMG automation