The Caprotti distribution

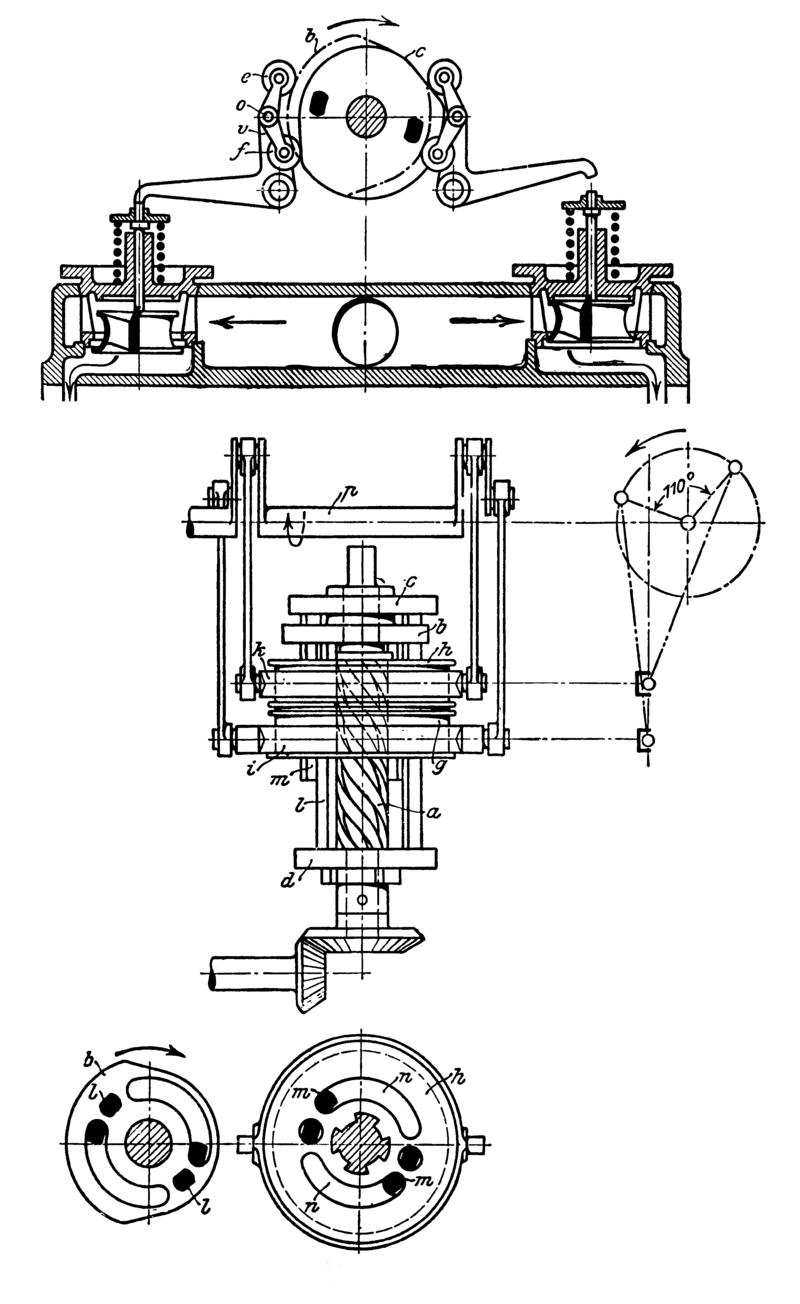

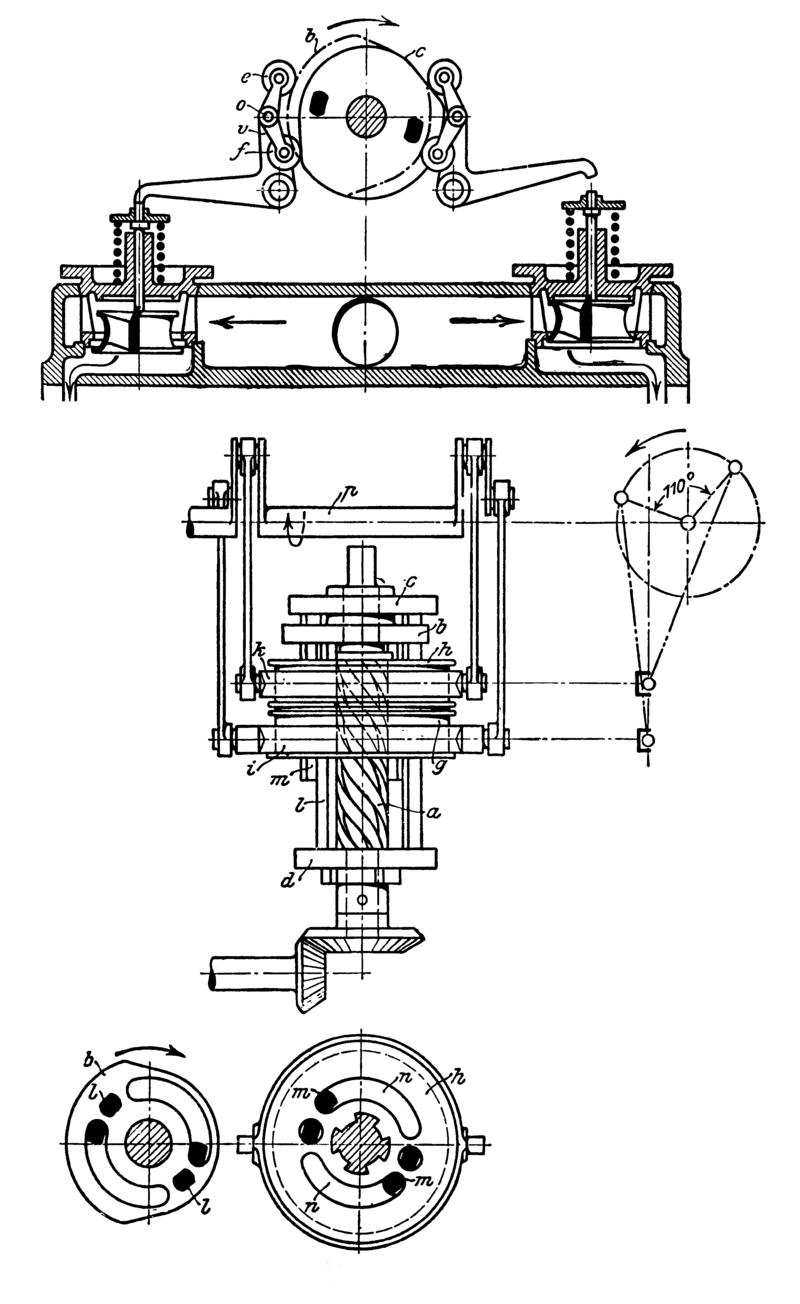

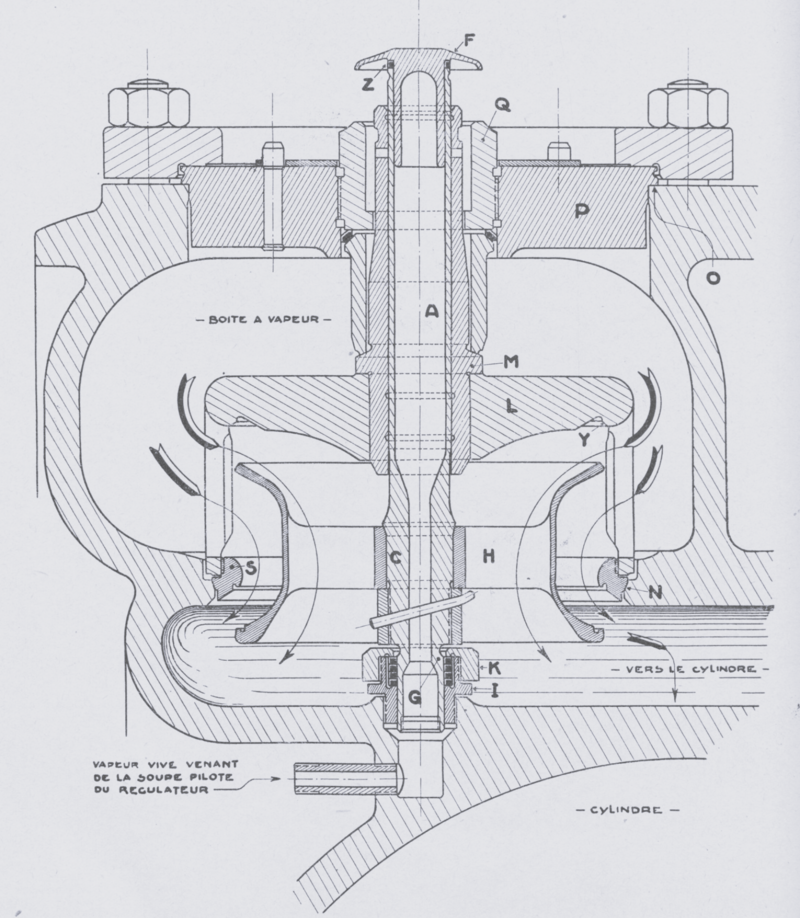

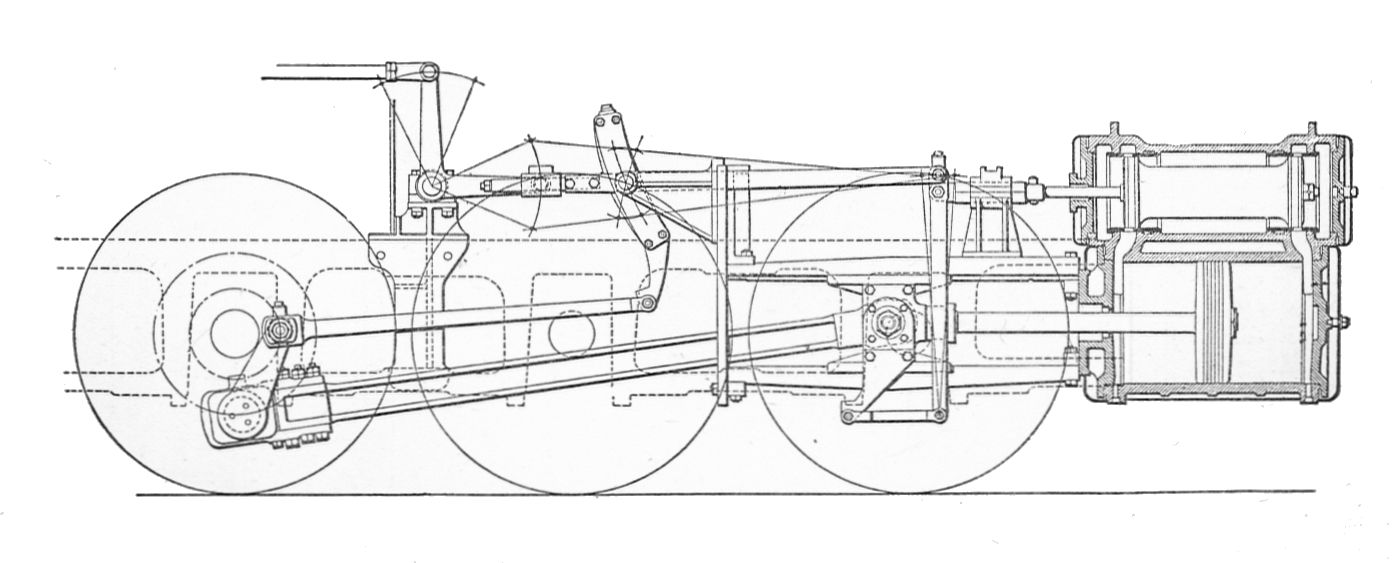

The Caprotti distribution is a distribution system, with distinct valves for the introduction and exhaust, of the steam produced by the boiler of a steam locomotive to the cylinders of its engine[1] invented by 'Italian engineer Arturo Caprotti.

The Caprotti distribution

The Caprotti distribution is a distribution system, with distinct valves for the introduction and exhaust, of the steam produced by the boiler of a steam locomotive to the cylinders of its engine[1] invented by 'Italian engineer Arturo Caprotti.

The innovation consisted in replacing the old and complicated system with a device, conceptually borrowed from the distribution applied to thermal engines, which by opening valves, controlled by cams. It introduced the steam with very precise and perfectly variable regulation within a large radius [2] avoiding the main problem that caused the low performance of the steam machines, the so -called steam lamination.

The Caprotti system required a greater constructive precision of the systems Traditional but on the other hand he allowed great advantages:

- simplified the biellism of the locomotives reducing their weight and inertial forces triggered by the various elements In motion.

- improved the performance of the locomotive by virtue of the precise regulation of the quantity of steam according to the need.

- consequently reduced the consumption of coal and increased the effective power of the locomotive. Europe and the United States. Find many applications also in the naval field, but its success was short because the steam engine falling in disuse, the use of the system is also laid down.

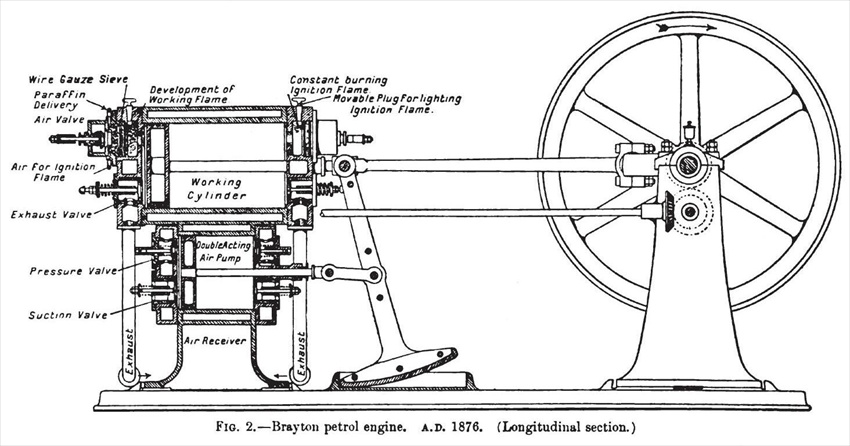

energy production with Brayton cycle

Le macchine funzionanti secondo il ciclo Brayton, risalgono agli albori della rivoluzione industriale e, per molti aspetti, introdussero innovazioni che sarebbero pi servite da spunto per lo svilupp0 dei motori a combustione interna a ciclo Otto e a ciclo Diesel, che ancora oggi utilizziamo.761 / 5.000The machines functioning according to the Brayton cycle, date back to the dawn of the industrial revolution and, in many respects, introduced innovations that would be more served as a starting point for the development of eight -cycle internal combustion engines and diesel cycle, which we still use today. The Brayton cycle engines that used piston kinemakers were quickly supplanted by eight and diesel cycle engines, but the idea that had inspired them survived and fully built in the gas turbines.

the systems for the production of Small scale energy, they can take advantage of the tatches available to create working machines with Brayton cycle, useful for the exploitation of small sources of thermal energy, deriving from fossil sources.

double-beat valve

The double-beat valve, drop valve or equilibrium valve is a type of poppet valve arranged to allow it to be opened against a high pressure with a minimum of force. One of its uses is in steam engines to admit steam to the cylinders and to release the exhaust. In stationary steam engines it is usually operated by trip valve gear while in railway locomotives a valve gear such as Caprotti is used.

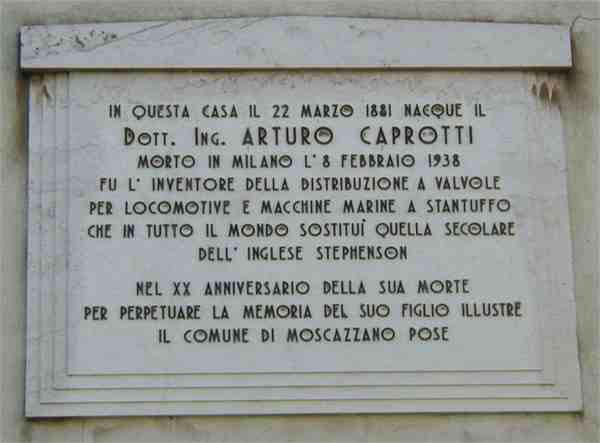

Ing. Arturo Caprotti

Arturo Caprotti (Moscazzano, 22 March 1881 â_" Milan, 8 February 1938) was an Italian engineer.

He was one of the last designers who made the history of steam traction.

He completed his studies and achieved, at just 21 years old, he graduated in Mechanical Engineering in Turin. He continued his studies and research abroad in such a demanding manner that around 1916 he designed and then patented an innovative system for distributing steam to the cylinders of the steam generators.

The Walschaert distribution

Until the 1920s, the steam locomotives started, for the distribution of the steam produced by the boiler to the engine cylinders, of dishes or cylindrical drawers designed by Stephenson, Gooch, Walschaerts and Allan. The most recent locomotives had largely adopted the distribution of Walschaert which presented better regulation and an increase in overall performance. However, the various systems have been united by a system of levers and postponement mechanically controlled by the geolism of the machine and rigidly dependent on the positions taken by it. A further inconvenience was determined by wear that increased the games, inevitable for the means always in motion, which further degraded its performance.

CMG automation

CMG automation